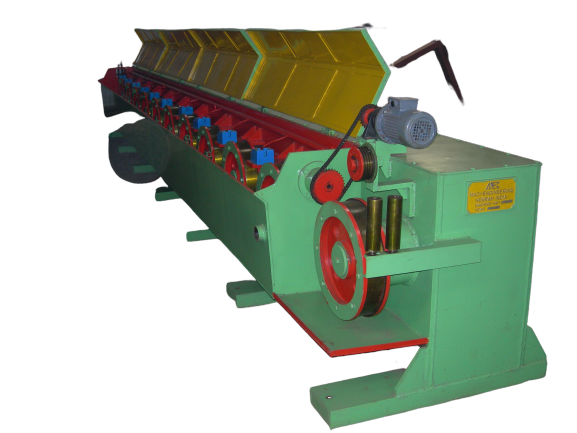

Manufacturer and Suppliers of Wire Drawing Machinery in Howrah

A wire is a circular, small diameter flexible rod. Wire drawing is a cold working process. It is an operation to produce wire of various sizes within certain specific tolerances. This process involves reducing diameter of thick wire by passing it through a series of wire drawing dies with successive die having smaller diameter than the preceding one. Mostly die are made by chilled cast iron, tungsten carbide, diamond or other tool material. The maximum reduction in area of wire is less than 45% in one pass.

Wire drawing, Making of wire, generally from a rod or bar. The wire-drawing process consists of pointing the rod, threading the pointed end through a die, and attaching the end to a drawing block. The block, made to revolve by an electric motor, pulls the lubricated rod through the die, reducing it in diameter and increasing its length. Fine wire is made by a multiple-block machine, because the reduction cannot be performed in a single draft.

Drawing is a widely used process because of its unbeatable advantages over any other procedure.

The advantages of wire and rod drawing of other applications are:

- Good surface finishing

- Adaptability to mass production

- Close dimensional control

- Improved dimensional properties

- Economic benefits