Manufacturer and Suppliers of Cold Roll and Ribbing Machinery in Howrah

Features:

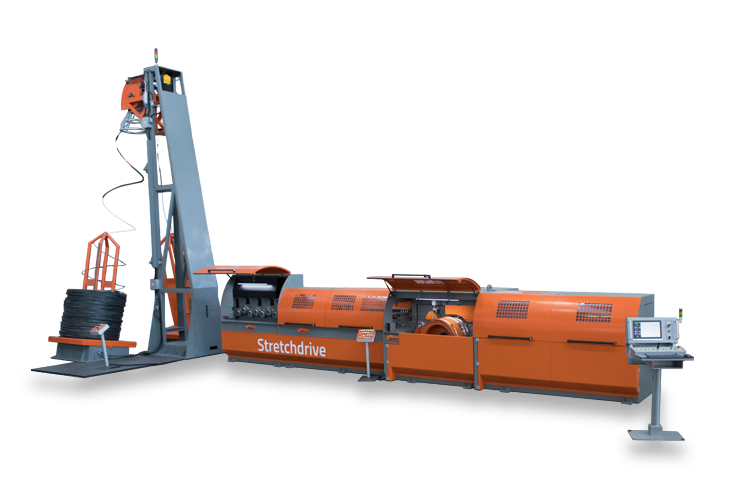

– Machinery to manufacture Cold Rolled Ribbed / Deformed Wire in diameters 3.5 mm to 12 mm

– Main Ribbing Machine made of heavy duty MS fabricated base frame on which a side support and movable support are linked with a stabilizing bar.

– Ribbing done by two Turk Heads each supported with three roller holders.

– A worm gear unit driven by geared motor unit moves each shaft axially in its support.

– Individual Turk Heads for adjustment of Rollers

– Water circulation in the machine provided for cooling

– All the roller holders controlled with a Digital Control

– Complete set of machinery offered including main Ribbing Machine and auxiliary machines like: Wire Drawing Machines, Wire Pointing Machine, Butt Welding Machine, Descaling Machine, Electric Control Panel Board, Automatic Wire Straightening and cutting Machine.